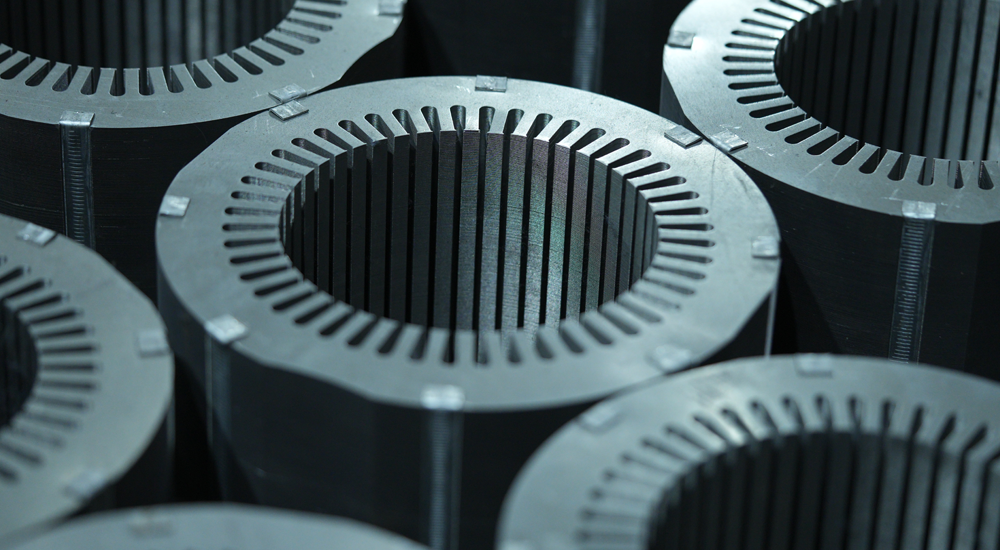

To support various industry applications, Galaxy Stamping provides a full range of value added services focused on stack based requirements. These include auto skewing, cleating, welding, D carburization, and aluminum die casting. Each process is executed with care to ensure durability and functionality. The welding division includes Argon and MIG stations for laminations up to 400 millimeters in diameter and up to 1000 millimeters in core length. The facility also includes several 10 ton and 20 ton hydraulic presses and three fully automated annealing furnaces that refine over 10 metric tons of material every day.