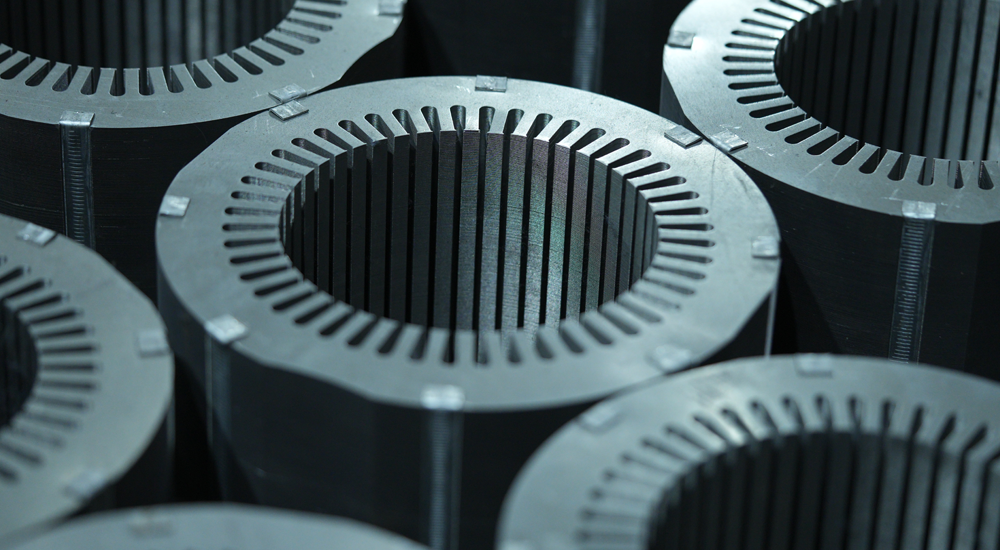

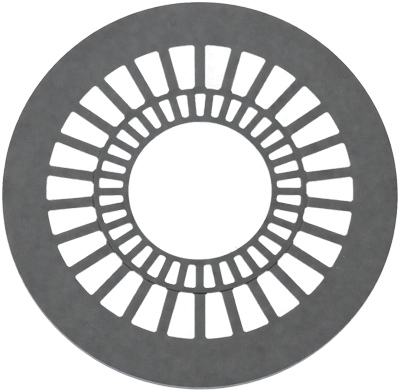

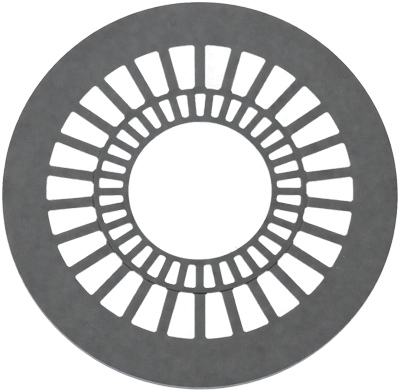

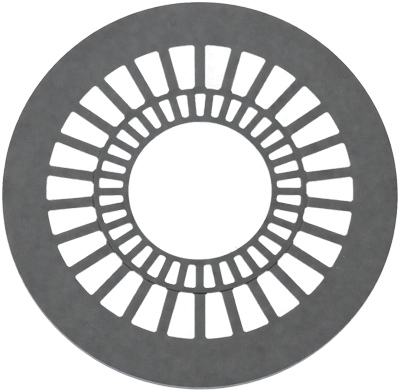

In Rajkot, Galaxy Stamping operates a 10,000 square meter manufacturing plant and produces over 18,000 metric tons of finished components annually. We utilize the latest state-of-the-art equipment and advanced processes to manufacture motor and generator laminations, along with value-added assembly operations.

Galaxy Stamping produces laminations for a wide range of applications, including submersible pumps, domestic appliances, automotive motors, fans, blowers, elevator and lift-duty motors, servo motors, industrial motors, alternators, generators, compressors, and transformer industries. Galaxy Stamping consistently delivers performance, trust, and reliability.

Galaxy Stamping produces laminations for a wide range of applications, including submersible pumps, domestic appliances, automotive motors, fans, blowers, elevator and lift-duty motors, servo motors, industrial motors, alternators, generators, compressors, and transformer industries. Galaxy Stamping consistently delivers performance, trust, and reliability.

The plant operates nine imported and two indigenous high-speed power presses ranging from 125 to 350 tons, designed for precision mass production. A fully automated slitting line handles coil widths of up to 1,250 millimeters. In the die-casting division, Galaxy Stamping operates a fully automated 100-ton machine with four rotary stations, along with two 160-ton machines, including one unit with a 15-kilogram aluminum shot capacity.

Preventive maintenance services ensure the full utilization of production resources. Creativity and superior technical expertise enable innovative and technically advanced turnkey solutions, delivering consistent and long-term manufacturing results.

Galaxy Stamping Private Limited boasts a state-of-the-art manufacturing facility for Cold Rolled Grain Oriented (CRGO) electrical steel, equipped with the latest technology to meet the diverse needs of the electrical and transformer industries. Our facility operates with high precision machinery, ensuring efficient and quality-driven production.

Over 1,50,000 sq.ft. dedicated area designed for efficient CRGO processing.

Target annual production capacity of 18,000 metric tons of CRGO laminations by FY 2027–28.

To support various industry applications, Galaxy Stamping provides a full range of value added services focused on stack based requirements. These include auto skewing, cleating, welding, D carburization, and aluminum die casting. Each process is executed with care to ensure durability and functionality. The welding division includes Argon and MIG stations for laminations up to 400 millimeters in diameter and up to 1000 millimeters in core length. The facility also includes several 10 ton and 20 ton hydraulic presses and three fully automated annealing furnaces that refine over 10 metric tons of material every day.

An optimum value chain needs trusted partnerships with suppliers and intelligently managed control over internal processes. The company sources various grades of electrical steel, including non grain oriented and semi processed materials, and transforms them into accurate loose laminations, interlocked and autoskewed stacks. Materials are sourced globally, ensuring uninterrupted and cost effective supply chains. Each batch of raw material is inspected before entering production.

Galaxy Stamping’s advanced tool room handles all tool maintenance and ensures flawless operation throughout the production cycle.It has CNC wirecut machines, EDM drills, high precision surface grinders, radial drill, cylindrical grinder, milling and precision lathe machines.

We design and source high precision tungsten carbide progressive dies from renowned manufacturers of world which ensures straight compliance to customer specific requirements. All carbide tools are engineered with interchangeable master inserts for long lasting punching life, outstanding dimensional accuracy and errorless maintenance. Each & every tool’s performance, maintenance and punching life data are thoroughly monitored and recorded.

A sophisticated system of order processing ensures the optimal progression through micro level production plans and control on securing a sufficient extent of customer awareness according to individual requirements on priority.

All departments operate under a centralized ERP system that connects every function and monitors materials, production, inspection, and output. Monthly targets are tracked and met with discipline, intelligent decision making, consistent quality products, perfect service and punctual delivery times.

With the core values of quality, technology, service, and delivery time Galaxy Stamping Pvt. Ltd. offer customers consistent quality products , perfect service and punctual delivery times.